Overview

According to the National Weather Service the Pottstown area receives about 43 inches of rainfall annually. That means that the runoff from the roof of a 73,000 sf building like ours is just under 2 million gallons per year. Normally that water would end up in the storm drains, we decided to try and make better use of it.

Rainwater Harvesting not only has benefits for us, but the local municipality as well. When we capture and store rainwater we ease the demand placed on the municipal storm water infrastructure during heavy downpours. When we use the stored water we reduce the demand on the public water supply. The rainwater itself is inherently free of minerals and additives such as chlorine so for process use, equipment and consumable parts last much longer.

For process and sanitary use, rainwater requires no treatment whatsoever. For sinks and showers all that is required is a commercial UV filter, much like the ones used for residential wells, to kill any bacteria. Since we only need to filter the drinking water, the designers sketched out a split plumbing system that separates the potable from non-potable uses.

[simpleviewer gallery_id=”5″]

Design

As we started to think about the design of the system, the first thing that became clear was we don’t use anywhere near 2 million gallons of water annually. The real question was, how much do we use and how much should we store to guarantee an uninterrupted supply during seasonally dry months. Those estimates were surprisingly straightforward.

We knew what equipment we intended to install and the process water requirements for each. We knew how many employees and shifts we anticipated and there are tables for typical water use per person. Working it out, we found we only needed to collect rainwater from about one quarter of the roof surface. For storage a single 26,000 gallon cistern was sufficient on paper, the final design included three. The second was to guarantee uninterrupted supply, the third was for unanticipated growth in water demand and, a backup in case there was a problem and a cistern needed to be drained for maintenance or repair.

Construction Details

Downspouts were to be removed and replaced by a pitched PVC pipe running in a “U” shape around the building. The collected rainwater then passes over vertical first rain refusal columns located inside the building. The columns capture roughly the first 500 gallons of runoff from the roof surface then slowly drain through a filter that is cleaned monthly. Capturing the initial runoff prevents dust, pollen and other contaminants from entering the cisterns and reduces the need for maintenance.

Any rainwater in excess of the storage capacity of the cisterns is returned to the storm water drain. Built into the foundation under the cisterns is a network of pipes for overflow, equalization, intake, telemetry and valves for isolation. Floats suspend the suction lines to prevent any debris from being drawn into the internal plumbing system.

BRAE also included a submersible pressure sensor to monitor the cistern levels and a controller in the booster pump package to eventually tie into our building automation system. The theory is, the pressure sensor measures the weight of the column of water above it. Knowing the dimensions of the cisterns and the weight of water, you can determine the level.

Observations

Thermal Expansion

Originally the collection manifold was designed to fit neatly outside the building. Shortly after construction began, our plumbing contractor came to me with a concern about the design. His group was responsible for building the collection manifold. He said something like “I know you guys are all really smart engineers but I did some math last night and through the seasons a 240′ length of PVC will expand and contract about a foot. No matter how I try to secure this to the outside of the building I think it’s going to tear itself free within a year.” Before he’d even finished saying the words, I knew he was absolutely correct.

Everyone on the design team had overlooked the effects of thermal expansion. Fortunately it wasn’t too late so we quickly revised the design to mount the collection manifold inside, where the temperature variations were more controlled. To date there hasn’t been a single problem with the revised design.

Telemetry

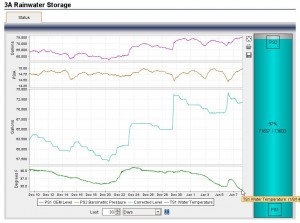

When the rainwater system was installed we hadn’t yet established the building automation system for monitoring. Back in the old days, I’d climb up the ladder and open the hatch to visually check the cistern levels then compare what I saw to the the submerged pressure sensor using a Fluke milliamp clamp meter and a little math. It was always pretty close.

When finally got the rainwater system integrated into the building automation, some things didn’t make sense. For example, over a weekend when there was no production usage and there was no rainfall, the historian was recording significant variations in the cistern levels. Over time, I realized the unexplained fluctuations had a correlation to barometric pressure.

The idea of measuring the cistern levels using a submerged pressure seemed sensible. A piezoelectric device, no moving parts, what could possibly go wrong? I at least assumed the small changes in atmospheric pressure over a 26′ diameter would be negligible. While it seemed a reasonable assumption, this was not the case. To accurately determine the cistern levels, we added a barometric pressure sensor to the system to correct the raw pressure measurement.

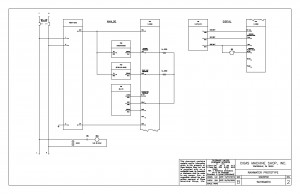

As the original BRAE controller wasn’t particularly compatible with our building automation, we designed an built a more suitable replacement. For rainwater system monitoring, the Control By Web X-320 product had exactly what we needed to solve the problem. As soon as we brought it online and applied the atmospheric correction to the raw submerged pressure sensor telemetry, the cistern level measurements immediately became completely stable and reliable.

Download:RW-rev-2-SCHEMATIC1-1

Freezing Weather

One concern I had in the design phase was whether or not we should expect problems with the cisterns freezing solid. Having grown up in this region I knew that occasionally arctic air masses could settle over this area for weeks at a time. BRAE’s opinion was, considering the mass of water involved (326 tons when the cisterns are full), it wouldn’t be a problem but just in case we made provisions in the design. To date, BRAE was correct and we’ve seen no extended freeze related problems whatsoever. As a precaution, we added a submersible temperature probe when we updated the controller design so if freezing should ever become a problem, we’ll know well in advance.

Moss

Before BRAE left we did a file walk around. It was a warm day and at the bottom of each cistern you could see it was a little damp. They assured us this was not a leak and perfectly normal and explained that because the air and water temperatures were not the same, the liner could sweat and that was the cause of the moisture. It seemed reasonable and I didn’t think much more of it until maybe two years later.

I happened to be walking past one day and noticed the dampness had vanished so I decided to take a closer look. Apparently the cool moist sheltered picoclimate in this tiny area is ideal for moss. Instead of a moisture ring, we now have a perfectly neat botanical seal around the bottom of each cistern.

Summary

Since it was installed the BRAE Rainwater Harvesting system has performed very well. It is simple, easy to maintain and reliable. Currently there is no municipal water supply connection to this building. All our water comes from the BRAE system.

Based only on the cost of municipal water it is difficult to say whether or not the system met the overall renovation projection design goal of a 2 year payback because the benefits of extended service life and lower maintenance costs on production machinery are somewhat intangible. While the installation cost was not trivial, it was reasonable. Compared to the installation cost of more conventional water supply alternatives, the system has clearly met the business goal.

Being independent of the municipal water supply has one additional benefit. Aside from not receiving a monthly water bill, planned or unplanned municipal water service outages have no impact on our production activities.